Page 353 - Fräsen Komplettprogramm

P. 353

Carbon steel Kohlenstoff Stahl

Alloy steel

Legierter Stahl

Quenched and tempered steel · Vergüteter Stahl

Hardened steel ·

Gehärteter Stahl

~60HRC ~68HRC

Stainless steel · Rostfreier Stahl

Copper alloy Kupfer Leg

Aluminum alloy Alu Leg

Titanium alloy Titan Leg

Heat resist alloy warmfeste Leg

Code key

ISO Kennzeichen

Graphics identification & application B232 Graphische Werkzeug- & Anwendungsbeschr.

Order form for non-standard products B497-B498 Bestellformular für Sonderwerkzeuge

B 353

Milling · Fräsen

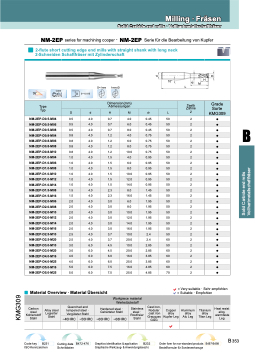

Solid Carbide end mills · Vollhartmetallschaftfräser NM-2EP series for machining cooper · NM-2EP Serie für die Bearbeitung von Kupfer

2-flute short cutting edge end mills with straight shank with long neck 2-Schneiden Schaftfräser mit Zylinderschaft

35o

Type

Coated

CrN

D 0~-0.015

D<1mm

1mm≤D

Dimension(mm)

L

Zähne

Z

Abmessungen

Typ D d H M d1 L

Teeth

Grade

Sorte

KMG309 ●

●

● B ●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

NM-2EP-D0.5-M04 NM-2EP-D0.5-M06 NM-2EP-D0.5-M08 NM-2EP-D0.8-M04 NM-2EP-D0.8-M06 NM-2EP-D0.8-M08 NM-2EP-D0.8-M10 NM-2EP-D1.0-M04 NM-2EP-D1.0-M06 NM-2EP-D1.0-M08 NM-2EP-D1.0-M10 NM-2EP-D1.0-M12 NM-2EP-D1.0-M14 NM-2EP-D1.5-M08 NM-2EP-D1.5-M16 NM-2EP-D2.0-M06 NM-2EP-D2.0-M08 NM-2EP-D2.0-M10 NM-2EP-D2.0-M12 NM-2EP-D2.0-M14 NM-2EP-D2.0-M16 NM-2EP-D2.5-M10 NM-2EP-D2.5-M20 NM-2EP-D3.0-M10 NM-2EP-D3.0-M20 NM-2EP-D4.0-M16 NM-2EP-D4.0-M25 NM-2EP-D5.0-M16 NM-2EP-D5.0-M25

0.5 4.0 0.7 0.5 4.0 0.7 0.5 4.0 0.7 0.8 4.0 1.2 0.8 4.0 1.2 0.8 4.0 1.2 0.8 4.0 1.2 1.0 4.0 1.5 1.0 4.0 1.5 1.0 4.0 1.5 1.0 4.0 1.5 1.0 4.0 1.5 1.0 4.0 1.5 1.5 4.0 2.3 1.5 4.0 2.3 2.0 4.0 3.0 2.0 4.0 3.0 2.0 4.0 3.0 2.0 4.0 3.0 2.0 4.0 3.0 2.0 4.0 3.0 2.5 4.0 3.7 2.5 4.0 3.7 3.0 6.0 4.5 3.0 6.0 4.5 4.0 6.0 6.0 4.0 6.0 6.0 5.0 6.0 7.5 5.0 6.0 7.5

4.0 6.0 8.0 4.0 6.0 8.0 10.0 4.0 6.0 8.0 10.0 12.0 14.0 8.0 16.0 6.0 8.0 10.0 12.0 14.0 16.0 10.0 20.0 10.0 20.0 16.0 25.0 16.0 25.0

Workpiece material

Werkstückstoff

0.45 0.45 0.45 0.75 0.75 0.75 0.75 0.95 0.95 0.95 0.95 0.95 0.95 1.45 1.45 1.95 1.95 1.95 1.95 1.95 1.95 2.4 2.4 2.85 2.85 3.85 3.85 4.85 4.85

Cast iron, Nodular cast iron Grauguss GGG

50 2 50 2 50 2 50 2 50 2 50 2 50 2 50 2 50 2 50 2 50 2 50 2 50 2 50 2 50 2 50 2 50 2 50 2 50 2 50 2 50 2 50 2 60 2 50 2 60 2 60 2 60 2 60 2 70 2

Material Overview · Material Übersicht

= Very suitable · Sehr empfohlen = Suitable · Empfohlen

B231

Cutting data Schnittdaten

~40HRC

~50HRC

B472-476

10°

H M

KMG309

Solid Carbide end mills

Vollhartmetallschaftfräser

d1

d

D