Page 42 - Fräsen Komplettprogramm

P. 42

General Turning /Allgemeine Drehbearbeitung, ISO Kennzeichnung

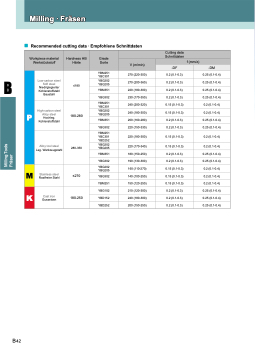

Milling · Fräsen

Recommended cutting data · Empfohlene Schnittdaten

Workpiece material

Hardness HB

Härte

≤180

180-280

280-350

≤270

Grade

Sorte

YBM251 YBC301

YBG202 YBG205

YBM351

YBG302

YBM251 YBC301

YBG202 YBG205

YBM351

YBG302

YBM251 YBC301 YBD252 YBG202 YBG205

YBM351

YBG302

YBG202 YBG205

YBG302

YBM251

YBG102

Cutting data

Schnittdaten

-DF

0.2 (0.1-0.3)

0.2 (0.1-0.3)

0.2 (0.1-0.3)

0.2 (0.1-0.3)

0.15 (0.1-0.3)

0.15 (0.1-0.3)

0.2 (0.1-0.3)

0.2 (0.1-0.3) 0.15 (0.1-0.3) 0.15 (0.1-0.3)

0.2 (0.1-0.3)

0.2 (0.1-0.3)

0.15 (0.1-0.3)

0.15 (0.1-0.3)

0.15 (0.1-0.3)

0.2 (0.1-0.3)

0.2 (0.1-0.3)

0.2 (0.1-0.3)

Werkstückstoff

Low-carbon steel Soft steel Niedriglegierter Kohlenstoffstahl Baustahl

High-carbon steel Alloy steel Hochleg. Kohlenstoffstahl

Alloy tool steel

Leg. Werkzeugstahl

Stainless steel

Rostfreier Stahl

K

V (m/min)

270 (220-350)

270 (200-360)

220 (180-300)

230 (170-350)

240 (200-320)

240 (180-350)

200 (160-280)

220 (150-330) 220 (180-300)

220 (170-340)

180 (150-250)

190 (130-300)

160 (110-270)

140 (100-250)

150 (120-250)

210 (120-300)

240 (180-300)

200 (150-250)

f (mm/z)

B

P

-DM

0.25 (0.1-0.4)

0.25 (0.1-0.4)

0.25 (0.1-0.4)

0.25 (0.1-0.4)

0.2 (0.1-0.4)

0.2 (0.1-0.4)

0.25 (0.1-0.4)

0.25 (0.1-0.4) 0.2 (0.1-0.4) 0.2 (0.1-0.4)

0.25 (0.1-0.4)

0.25 (0.1-0.4)

0.2 (0.1-0.4)

0.2 (0.1-0.4)

0.2 (0.1-0.4)

0.25 (0.1-0.4)

0.25 (0.1-0.4)

0.25 (0.1-0.4)

M

Cast iron

Gusseisen

180-250 YBD152

YBD252

B42

Milling Tools Fräser